Production forests are an important asset for environmental balance and economic sustainability of a country. However, production forest management often poses complex challenges, especially in maintaining a balance between the use of natural resources and environmental conservation.

One approach applied to strengthen the sustainability of forest management is through the Reduced Impact Logging-Carbon (RIL-C) method, which emphasizes selective tree cutting by minimizing environmental impacts and reducing carbon emissions from logging.

PT Wana Bakti Persada Utama (WBPU) uses two of the latest technologies in an effort to optimize the implementation of RIL-C in the company's production forest concession area. The two technologies are Light Detection and Ranging (LIDAR) and Logfisher.

Teknologi LiDAR

On March 29, 2024, PT WBPU together with DJI (one of the drone development companies) conducted training on the use of LIDAR drones in the production forest concession area owned by PT WBPU in the Hulu Kelay area, Berau, East Kalimantan. In this training, PT WBPU's logging area mapping staff were trained to be able to operate drones equipped with LiDAR technology.

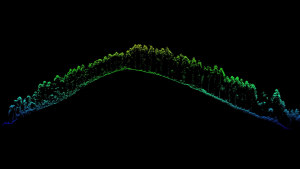

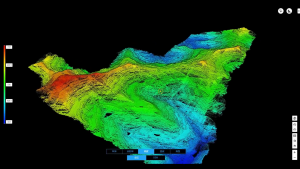

LiDAR itself is a long-distance mapping technology that uses laser pulses (which use laser beams emitted to objects to produce elevation data) to measure the distance to the earth's surface. In the context of production forests, LIDAR is used to map and monitor forest conditions accurately and efficiently. PT WBPU noted several main benefits of using LIDAR in implementing RIL-C in production forest areas, including:

Forest Structure Mapping: LiDAR can provide a deep understanding of forest structure, including tree height, canopy cover, and vegetation distribution. This information allows operators to make better decisions about which trees to cut, minimizing environmental damage.

Sensitive Area Identification: With the help of LiDAR, sensitive areas such as rivers, swamps, and wildlife habitats can be identified with high accuracy. This allows operators to avoid these areas during the cutting process, maintaining the integrity of the forest ecosystem.

Change Monitoring : LiDAR also allows monitoring of changes in forest structure over time. This helps in evaluating the effectiveness of forest management practices and provides important insights for long-term planning.

Logfisher Technology

Logfisher heavy equipment technology plays an important role in the application of the Reduced Impact Logging-Carbon (RIL-C) method for production forest companies. Logfisher is heavy equipment specifically designed for logging and wood moving operations in the forest. This tool usually consists of a crane with a long arm that is capable of lifting and moving felled tree trunks without damaging the surrounding vegetation.

The use of Logfisher in the RIL-C method in the PT WBPU concession area is expected to provide several important benefits, including:

Reduces Soil and Vegetation Damage: Logfishers are able to lift tree trunks from the ground without having to drag them. This reduces damage to soil and vegetation that occurs during the logging process.

Reduced Logging Routes: These tools allow moving logs through fewer and narrower routes, reducing the land clearing required to create logging routes.

Increased Efficiency: Logfisher increases the efficiency of the logging process because it can lift and move trees quickly and precisely. This reduces operational time and reduces carbon emissions from heavy machines operating longer.

Minimized Carbon Emissions: By reducing soil and vegetation damage and increasing operational efficiency, Logfisher helps minimize carbon emissions associated with logging. This is in line with RIL-C's goal to reduce the carbon impact of logging activities.

The process of implementing Logfisher in the RIL-C method involves several key steps, including planning and preparation, determining the logging route and the location of the trees to be felled carefully to minimize environmental impacts. GPS and mapping technology were used to plan the optimal route for the Logfisher.

Operator Training Logfisher operators are specially trained to operate this machine in an environmentally friendly and efficient manner. They are also trained to respond to changing field conditions.

Monitoring and Evaluation, after implementation, the logging and timber removal processes are monitored continuously to ensure that environmental impacts are minimized. Periodic evaluations are conducted to identify areas of improvement and ensure compliance with RIL-C standards.

The application of LIDAR and Logfisher technology has brought significant changes in the way PT WBPU understands and manages production forests. By utilizing these two technologies optimally, PT WBPU can strengthen the implementation of RIL-C principles, maintaining a balance between utilization of forest resources and preserving the environment for future generations.